Tempering systems from C-SYS I Cleaning Systems are as individual as the workpieces to be cooled / heated themselves: Not only the different variations of our workpiece heating and cooling processes, but also the overall layout of our tempering systems is tailored to your workpiece and process.

For every tempering system, environmental factors like cycle time, workpiece shape, workpiece mass, material of workpieces, ambient temperature and naturally also the end temperature to be achieved are considered.

In addition, the temperature curve of each workpiece type is different and is examined in detail by C-SYS I Cleaning Systems in advance with tests.

The results are calculated in a data matrix, and the ideal cooling or heating process as well as the number of stations and thus the total length of the system is specified and provided. This not only reduces energy consumption, but the fluctuation range of the end results is also cut down to a minimum.

Our tempering systems are divided into several stations each, where the workpieces, depending on the entry temperature, are cooled in different places and with different procedures . Intelligent sensors in each station also measure the entry and end temperature in defined places on the workpieces. The measured values are evaluated simultaneously and the system decides independently whether further cooling stations are required or whether the workpieces can be passed through. At the same time, the ACTUAL temperature in each station is compared to the matrix from the previous tests, which is specifically adapted to the matrix – this also means that a reheating of the heat stored in the core is controlled, and a consistent end result is achieved.

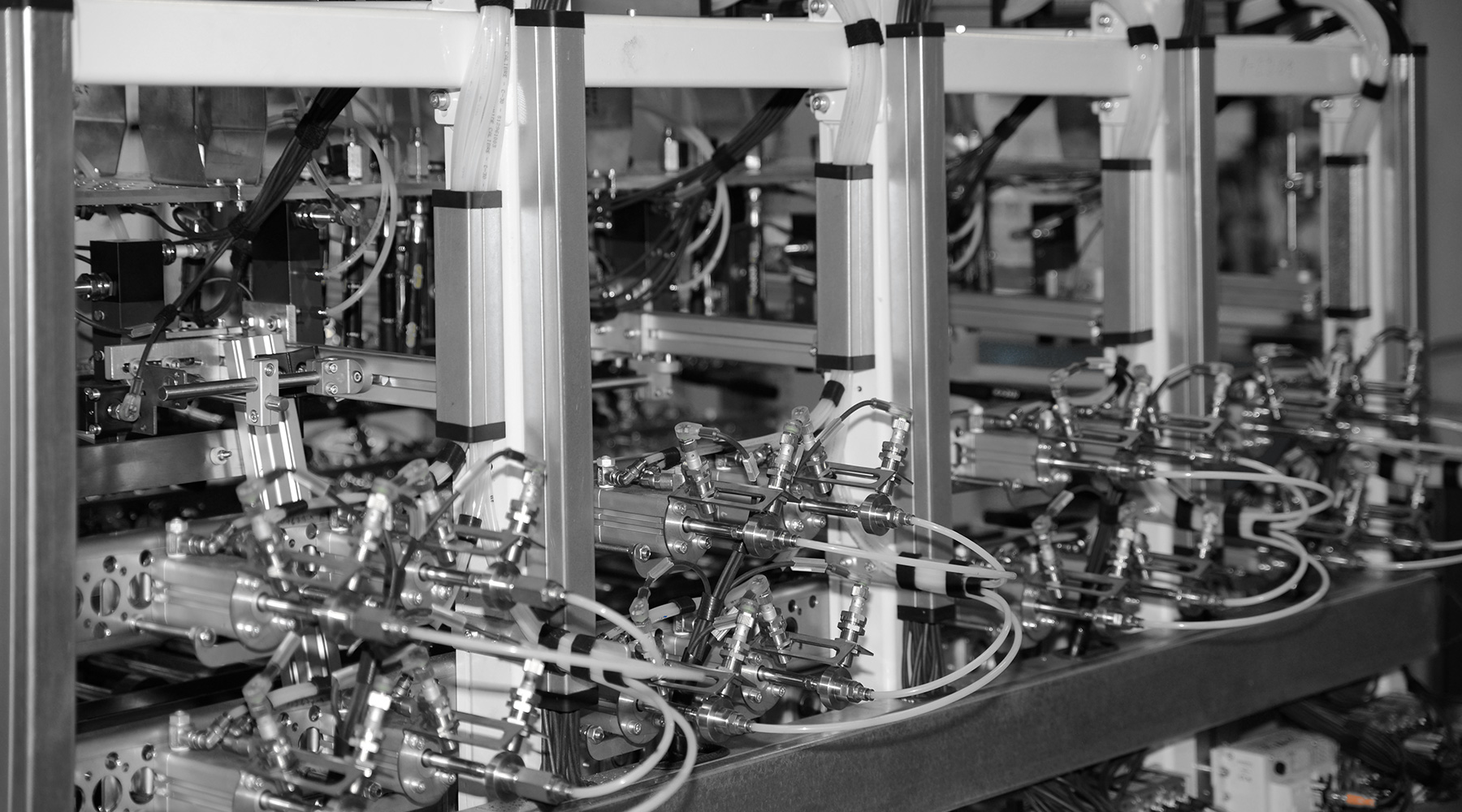

The tempering systems from C-SYS I Cleaning Systems can even operate without cooling units: The required cooling capacity is then achieved with special air circulation and compressed air nozzle assemblies. This ensures a precise and highly efficient cooling process. Lead times are also avoided – the C-SYS I Cleaning Systems tempering systems are ready for operation from the very start!

External view of the sensors and actuators of a temperature control cooling tunnel

The heating or controlled slow workpiece cooling according to thermal processes often plays a crucial role, which can be easily solved with the tempering systems from C-SYS I Cleaning Systems.

With the abrupt cooling of some workpieces after production or after certain processes, there can be high tensions and deformations up to the formation of cracks. As a preventive measure, we can also equip our tempering systems with special hot air nozzles and different heating systems. Incremental cooling or heating occurs again in a specific number of stations – of course with the same permanent monitoring for a precise end result!

In the field of tempering systems, C-SYS I Cleaning Systems definitely does not offer an all-purpose product, but customised solutions at the highest level – and in the smallest space!

The C-SYS I Cleaning Systems tempering systems provide the following benefits:

- Exact measuring and tests of workpieces before project start

- Consistent temperatures at the system output

- Highly efficient cooling or heating of workpieces

- Energy-saving design with systems directly adapted to the workpieces

- No high-maintenance peripheries

- No decentralised cooling systems required

- Shortest designs

- Simultaneous cooling and heating at different workpiece areas possible

C-SYS I Cleaning Systems offers the following additional options:

- Stand-alone control unit, incl. CPU and display

- Optional own air supply

Automotive (truck / passenger car)

- Motor: Crankcase, cylinder head, crankshaft, connecting rod, balance shaft etc.

- Gear unit: Gear wheels, CV transmission shafts etc.

- Steering: Steering gearbox etc.

- Drive: Cardan shaft etc.

- Chassis: U-joint crosses, wheel carriers etc.

- E-mobility (electric motor): Rotor shaft, stator etc.

DEUTSCH

DEUTSCH ENGLISH

ENGLISH