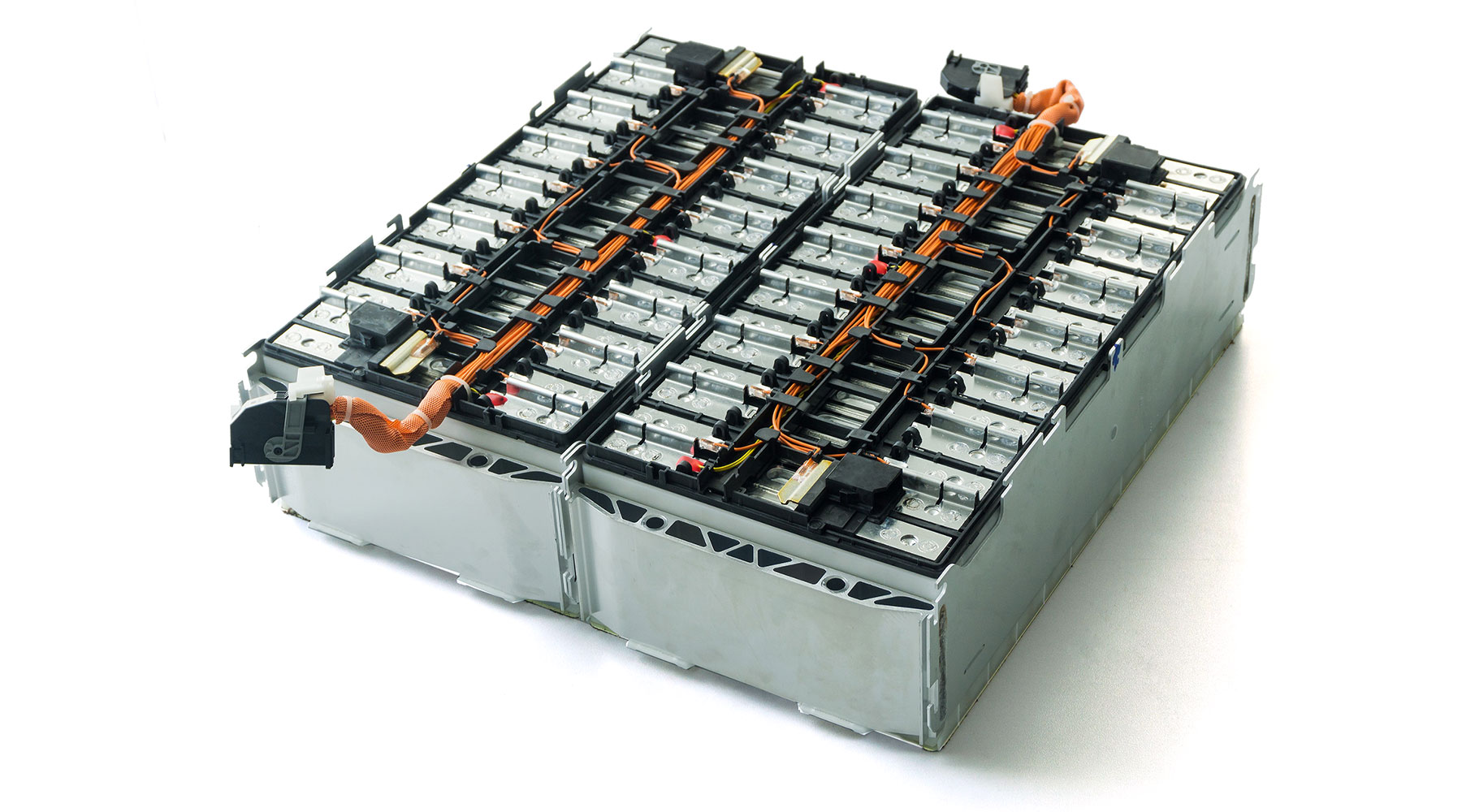

Cleaning of battery packs / rechargeable packs in automotive as well as other production lines

Production, assembly, transport, storage, … There are many environmental factors which have a negative impact on the cleanliness of finished products or assemblies. Particularly in the highly sensitive production and assembly of battery modules, rechargeable battery packs or battery packs for drive batteries, re-contamination plays a significant role.

Often, it is not enough here to clean these components with simple product solutions. Standardised procedures such as “ionised cleaning” can only be used conditionally, and are often not sufficient for all types and sizes of battery modules or their production processes (cycle times).

The technical cleanliness requirements always govern these areas more precisely.

In this context, independent of the respective technical cleanliness requirements, we create specialised systems and devices for the cleaning of battery modules, battery cells, battery packs, ... which take the production environments with regard to cycle time, workpiece position, transport, and most of all the quantity and quality of the introduced contaminations into consideration.

High demands on the technical cleanliness are crucial for error-free functioning of the storage components such as battery modules or individual battery cells. We take these requirements seriously and create a fully functional overall system, which easily meets these demands. From insertion of the drive battery components into the cleaning system to internal transport, the cleaning system and often forgotten topics such as: “where do particles fall during cleaning?” Nothing is left to chance here!

The combination of dry-cleaning processes for the battery packs assembly provides the following benefits:

- No liquids used

- Combination of air blower cleaning, suction system and precise compressed air cleaning as required

- Completely independent with blast air generator and finest particle suction system, compressed air generator as required

- Flow-optimised nozzle housing for particularly laminar particle removal

- From simple device to fully automated NC system

- Flexible designs and controls for even application on all contours, sides and surfaces

- Fully parameterisable control systems and axes

- Precise workpiece cleaning

- Concept for each cycle time, fully automatic or manual loading

DEUTSCH

DEUTSCH ENGLISH

ENGLISH